Best Professional Kitchen Equipment 2025: Complete Guide

Optimise your commercial kitchen with expert picks, buying criteria, and maintenance hacks for 2025—discover what pros rely on next. Like a maestro tuning an orchestra before the first downbeat, you'll need the right instruments to run a kitchen that hums. You’ll get clear criteria for choosing durable, energy-smart ovens, combi ranges, refrigeration, and dishwashers that cut costs and downtime. Practical buying tips, maintenance checklists, and performance metrics will help you avoid costly mistakes—keep going to build a kitchen that actually performs under pressure.

Key Takeaways

- Prioritize durability, energy efficiency, and total cost of ownership when selecting ranges, refrigeration, prep, and dishwashing equipment.

- Choose versatile, high-throughput combi ovens, robust gas ranges, and programmable finishing devices for consistent culinary results.

- Opt for modular refrigeration and holding units with smart sensors for cold-chain integrity and reduced food waste.

- Select prep and portioning tools with easy-clean removable parts to speed workflow and lower sanitation labor.

- Require vendor service plans, warranties, staff training, and compliance documentation as part of any equipment purchase.

Introduction to Professional Kitchen Equipment in 2025

You rely on specialized machines in modern kitchens because they boost consistency, speed, and safety while cutting labor and waste.

This guide breaks down the essential categories—cooking ranges and combi ovens, refrigeration, food prep equipment, dishwashing systems, and precision tools like sous-vide and vacuum sealers—so you can match features to workflow.

Read on to compare performance metrics, energy use, and maintenance needs that determine long-term value.

Why modern kitchens rely on specialized machines

Why do modern kitchens increasingly depend on specialized machines? You need predictable output, speed, and efficiency to keep creative freedom alive; specialized machines deliver both. They minimize manual errors, let you scale menus without sacrificing quality, and free staff for higher‑value tasks.

- You’ll use conversation prompts to align teams during vendor negotiations and to clarify warranty coverage.

- You’ll manage budget constraints by choosing modular equipment that supports cross‑function collaboration.

- You’ll reduce onboarding time when staff training focuses on fewer, smarter machines.

- You’ll protect operations by insisting on service plans and clear performance metrics.

Adopt gear that extends your options, not your constraints. Be deliberate: weigh total cost of ownership, training needs, and supplier reliability before committing.

Overview of categories covered in this guide

Having established how specialized machines preserve creativity by boosting predictability, speed, and efficiency, this section maps the equipment types you'll evaluate for a 2025 professional kitchen.

You'll get concise, category-by-category breakdowns: cooking and holding, refrigeration, prep and portioning, dishwashing, ventilation, and point-of-sale/inventory systems.

For each, you'll see performance metrics, space and energy requirements, vendor ethics notes, and simple maintenance plans so you can decide freely.

We'll also flag ancillary considerations—color psychology for guest-facing gear, staff scheduling impacts, insurance coverage implications, and energy tariffs that affect operating cost.

Startup incubation tips show scalable buys, and two word discussion ideas help guide team decisions.

Use this as a practical shopping roadmap.

Best Hot Chocolate Makers 2025 – Buyer’s Guide & Top Picks

Looking for barista-quality hot chocolate at home? You’ll get precise heat control, consistent texture, and simplified barista workflows from the right machine. Focus on build, pump strength, and programmable temperature for professional results. Prioritize models that support chocolate tempering and integrate with beverage stations.

- Choose units with easy equipment care and removable parts for quick cleaning.

- Verify cocoa sourcing compatibility—real couverture vs. mixes affects viscosity and taste.

- Look for adjustable frothers and dosing to match service volume and freedom of creativity.

- Consider serviceability, spare parts, and compact footprint for tight counters.

You want durable performance that respects your craft. Pick a maker that streamlines prep, minimizes downtime, and elevates every cup without compromising control.

Best Candy Floss Machines in Europe – How to Buy, Use & Maintain

Want perfect, fluffy candy floss that holds up at fairs, pop‑ups, or busy cafés? Choose a machine that balances output, durability and portability. Look for clear Europe pricing and warranty terms so you can compare total cost. Check safety standards compliance, ear‑marked guards, and CE markings before purchase. Measure power requirements against your venue’s supply; commercial models need higher amps and stable voltage. Test operating noise—quieter units keep you flexible in shared spaces. Master sugar ratios and use quality stickable sugar or candied floss mixes to ensure consistent strands and minimal clogging. Clean after each shift, inspect belts and heating coils, and schedule professional servicing annually to maintain performance and meet local regulations.

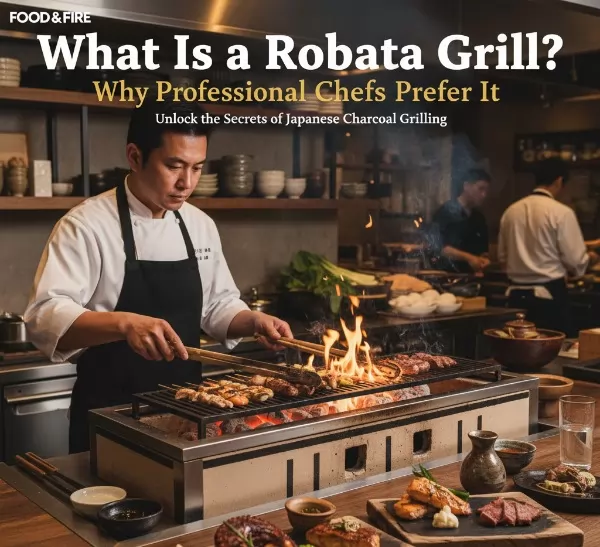

What Is a Robata Grill? Why Professional Chefs Prefer It

If you’ve mastered candy floss for busy service, switching attention to a robata grill will show how different heat control changes the game for proteins and vegetables. You’ll get concentrated roast flavor from direct charcoal, and precise flame control lets you sear without overcooking. Focus on consistent heat distribution across grates; that’s how you deliver repeatable results quickly.

- Choose grills with adjustable flame control and reliable fuel sourcing.

- Inspect venting challenges and kitchen layout before installation.

- Train staff on safety protocols and temperature staging.

- Prioritize models with removable grates for cleaning and maintenance.

You’ll appreciate how a robata’s simplicity gives culinary freedom while demanding disciplined technique and sound operational planning.

Bone Saw Machines – The Secret Weapon of Meat Processing Pros

Curious how professional butchers turn whole carcasses into precise portions quickly? You’ll rely on a bone saw to slice through dense joints with speed and consistency, boosting throughput in any meat processing operation. Choose a rugged machine with easy-to-change blades and clear guarding so you can follow strict safety protocol without slowing down.

Regular blade maintenance and alignment keep cuts clean, reduce downtime, and extend blade life. Implement sanitation standards—quick disassembly, washdown-friendly materials, and scheduled deep cleans—to prevent contamination and keep inspections simple.

Proper technique plus the right machine drives waste reduction by maximizing usable meat and trimming time. You’ll gain control, efficiency, and confidence when you pair operator training with disciplined maintenance routines.

GIORIK Italy Gas Salamander – Professional Kitchen Upgrade Review

Looking for a reliable finishing tool that speeds service and elevates plating precision? You’ll find the GIORIK Italy gas salamander is a professional upgrade that boosts kitchen efficiency without sacrificing control. It’s compact, rugged, and gives you precise heat control for gratinées, finishing proteins, and crisping surfaces fast. You’ll appreciate energy savings from targeted burners and quick recovery times, which cut wasted fuel during service.

- Rapid, even browning with adjustable flame zones

- Sturdy stainless build for heavy use and easy cleaning

- Intuitive controls for repeatable finishing results

- Lower operating costs through efficient burner design

You’ll gain freedom in timing and plate presentation, trusting a tool built for intense, consistent performance.

Why Chefs Love Woodfired Italian Style Pizza Ovens

While a salamander brings precise, high-heat finishing to plated dishes, woodfired Italian-style pizza ovens offer a different kind of mastery: they marry intense, radiant heat with artisanal control to produce crusts and toppings you can’t replicate with conventional equipment.

You’ll value how wood fired chambers reach 800–900°F quickly, creating rapid oven spring and leopard-spotted charring while sealing moisture.

Italian style brick or steel floors deliver even conduction; dome geometry focuses radiant heat.

For practical kitchens, these ovens increase throughput, simplify temperature zoning, and yield consistent results when you manage fuel, airflow, and stone maintenance with disciplined routines.

How to Choose the Right Professional Kitchen Equipment

When choosing professional kitchen equipment, you’ll focus on durability, efficiency, cost, and brand reputation to match your service demands and budget.

Compare specifications and real-world performance across categories using clear comparison tables to spot trade-offs and long-term value.

I’ll show you which metrics matter most for each equipment type so you can make confident, cost-effective choices.

Key factors: durability, efficiency, cost, brand reputation

Why does durability, efficiency, cost, and brand reputation matter so much when you outfit a professional kitchen? You need equipment that lasts, saves energy, fits budgets, and comes from suppliers you can trust. Consider these core checks before buying:

- Assess durability tradeoffs versus upfront price; know the cost of ownership over expected life.

- Prioritize energy efficiency and factor in maintenance routines to preserve performance and lower bills.

- Examine warranty considerations closely and verify supplier credibility—reputation affects parts, service speed, and spare availability.

- Calculate total operating costs: fuel or electric use, filter and part replacements, and expected downtime impact.

Make choices that free you to run service reliably; smart selection reduces surprises and keeps your kitchen profitable.

Comparison tables across categories

Because comparing specs side-by-side makes differences obvious, you should use clear, standardized tables for each equipment category—ranges, refrigerators, dishwashers, fryers, and prep stations—so you can judge capacity, energy use, footprint, warranty, and total cost of ownership at a glance.

Create columns for key metrics: dimensions, throughput, energy efficiency, maintenance intervals, warranty options, and staff training needs.

Add notes on culinary impact—how a range supports bold flavors or a prep station shapes cafe ambiance.

Include a section for portable solutions and mobile setups if you value flexibility.

Sort rows by total cost of ownership and filter by footprint or energy class to match your space and sustainability goals.

Update tables annually to stay precise and actionable.

Maintenance & Safety Tips for Professional Kitchen Machines

You’ll keep machines reliable by establishing strict cleaning routines that target food traps, grease build-up, and electrical components.

Follow current safety standards and verify certifications, lockout/tagout procedures, and staff training to prevent accidents.

With scheduled servicing and proper use you’ll extend equipment lifespan and protect your kitchen’s productivity.

Cleaning routines, safety standards, extending lifespan

How often should you clean and inspect each machine to keep it running safely and efficiently? You should follow strict cleaning routines and safety standards: daily surface wipes, weekly deep cleans, monthly inspections, and quarterly professional servicing. Prioritize maintenance tips that consider durability factors and brand reputation when ordering parts.

- Daily: sanitize, check seals, and clear debris.

- Weekly: disassemble, descale, lubricate moving parts, record findings.

- Monthly: test safety interlocks, tighten connections, replace worn gaskets.

- Quarterly: calibrate controls, verify electrical grounding, schedule certified technician.

Stick to manufacturer guidelines to avoid voiding warranties. Document every action so you retain control and freedom over operations, reduce downtime, and extend lifespan while ensuring compliance with local regulations and workplace safety standards.

Future Trends in Kitchen Technology 2025 and Beyond

You’ll see smart appliances and interconnected systems streamline prep, monitoring, and maintenance to cut labor and error.

Expect AI-driven cooking to standardize recipes, optimize energy use, and assist staff with real-time adjustments.

Sustainability will be baked into equipment design—energy-efficient motors, waste-reduction features, and recyclable materials will become baseline requirements.

Smart appliances, AI driven cooking, sustainability

Curious how kitchens will cook, conserve, and connect in the next decade? You’ll see smart appliances and AI driven systems reshape professional kitchens, giving you control, speed, and savings. Expect precise temp control, predictive maintenance, and integrated sensors that boost energy efficiency and drive waste reduction. Data analytics will inform menu engineering and supply ordering so you’ll cut costs and spoilage.

- Networked ovens that learn your recipes and optimize cycles

- Refrigeration with real-time spoilage alerts and inventory tracking

- AI driven frying and sous‑vide that ensure consistency and speed

- Energy management hubs that coordinate load and reduce bills

Adopt these tools to gain freedom: scale operations, reduce labor strain, and meet sustainability targets with measurable results.

Frequently Asked Questions

Elevating Commercial Kitchen Efficiency in Hospitality & Food Service

In the competitive world of hospitality brand efficiency, running a commercial kitchen is about more than equipment—it’s about building a system that supports consistent, high‑quality service. Durable tools, streamlined workflows, and safety‑first maintenance form the backbone of reliable operations across restaurants, hotels, and catering businesses.

Key Strategies for Restaurant Brand Workflow Systems

To achieve true restaurant workflow optimization, focus on these proven strategies:

- Invest in transparent total‑cost metrics: Evaluate lifetime value, not just upfront costs.

- Prioritize modular designs: Flexible layouts adapt quickly to new menus or service demands.

- Choose easy‑clean equipment: Hygiene and speed of cleaning directly impact efficiency and safety.

- Train teams on routine checks: Preventive maintenance reduces downtime and protects brand reputation.

- Demand vendor transparency: Partner with suppliers who provide clear data on durability, warranties, and sustainability.

- Keep detailed records: Track performance, costs, and maintenance schedules to inform smarter decisions.

- Stay curious about innovations: Adopt emerging technologies in food service operations to stay ahead of competitors.

Why Efficiency Matters in Hospitality & Food Service

For leaders in restaurant management and food service operations, efficiency is not just about saving time—it’s about:

- Protecting margins in a competitive industry.

- Ensuring safety for staff and customers.

- Strengthening brand reputation through consistent quality.

- Driving long‑term success in the hospitality industry.

When smart investments meet disciplined processes, your kitchen becomes not just efficient—but a true competitive advantage.

At KitchenPro we support gastronomy professionals with kitchen equipment that combines innovation, reliability, high performance and sustainable energy saving solutions. Upgrade your kitchen easily and efficiently – see KitchenPro catalog with products.